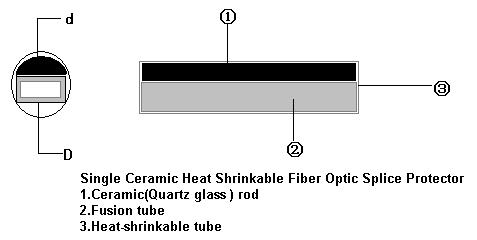

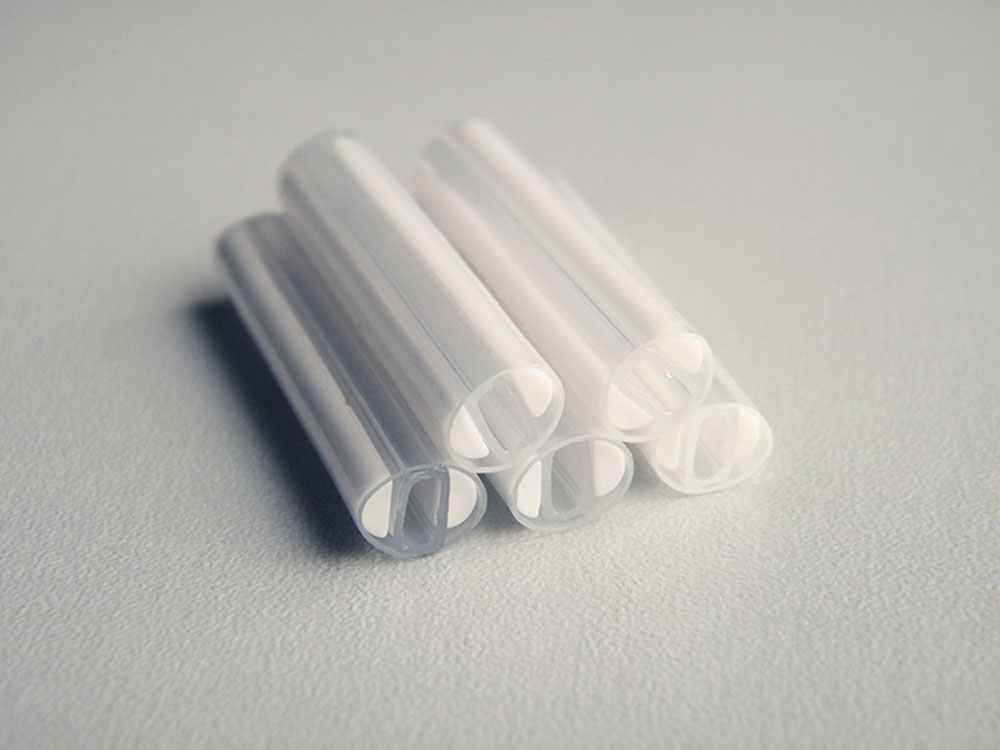

FOSP Heat Shrinkable Ribbon Fiber Optic Splice Protector

Applications

Special design by the cross linking polyolefin melt pipe, and composed of ceramic(Quartz glass) fiber connection protection components, no influence of fiber optical properties

Characteristics Protect and improve in mechanical strength Simple operation, reduce the risk of fiber damage during installation Seal structure, good resistant of temperature and humidity | Operating temperature range Operating temperature : -45?C~100?C / -45?C~135?C Minimum shrink temperature : 80?C Minimum fully recovery temperature : 120?C |

Technical Indicators

Performance | Test Method | Typical data |

Tensile strength | ASTM D 2671 | 16MPa |

Elongation at break | ASTM D 2671 | 700% |

Density | ISO R1183D | 0.94g/cm3 |

Dielectric strength | IEC243 | 25KV/mm |

volume resistance | IEC243 | 1015Ω.cm |

Length changes | ASTM D 2671 | ±5% |

Product Dimensions

Specifications | Sleeve length(mm) | fusion tube (D)High*(mm) | Ceramic rods(d) | ||

length(mm) | (mm) | Height(mm) | |||

FOSP-4RD | 41.5±0.5 | 1.2*2.2 | 39.5±0.5 | 3.0±0.1 | 1.5±0.1 |

FOSP -4RS | 41.5±0.5 | 1.2*2.2 | 39.5±0.5 | 3.0±0.1 | 1.5±0.1 |

FOSP -6RD | 41.5±0.5 | 1.2*2.7 | 39.5±0.5 | 3.0±0.1 | 1.5±0.1 |

FOSP -6RS | 41.5±0.5 | 1.2*2.7 | 39.5±0.5 | 3.0±0.1 | 1.5±0.1 |

FOSP -8RD | 41.5±0.5 | 2.3*3.6 | 39.5±0.5 | 4.0±0.1 | 2.0±0.1 |

FOSP -8RS | 41.5±0.5 | 2.3*3.6 | 39.5±0.5 | 4.0±0.1 | 2.0±0.1 |

FOSP -12RD | 41.5±0.5 | 2.5*3.8 | 39.5±0.5 | 4.0±0.1 | 2.0±0.1 |

FOSP -12RS | 41.5±0.5 | 2.5*3.8 | 39.5±0.5 | 4.0±0.1 | 2.0±0.1 |

FOSP-6RDT | 41.5±0.5 | 2.8*1.7 | 39.5±0.5 | 3.0±0.1 | 1.5±0.1 |

FOSP-12RDT | 41.5±0.5 | 3.5*2.2 | 39.5±0.5 | 4.0±0.1 | 1.5±0.1 |